Introduction to Polysorbate 20

In the realm of modern product formulation, the challenge of blending oil and water is a constant hurdle, one that emulsifiers like Polysorbate 20 adeptly overcome. As a non-ionic surfactant derived from natural sources, Polysorbate 20 has carved a niche as an indispensable ingredient across the cosmetic, food, and pharmaceutical sectors. Its ability to create stable, homogeneous mixtures not only enhances product efficacy but also extends shelf life and improves user experience. This comprehensive guide delves into the intricate details of Polysorbate 20, exploring its chemical makeup, multifaceted benefits, diverse applications, and safety profile. By understanding its roles, manufacturers and consumers alike can appreciate why this emulsifier is a staple in countless everyday products, from luxurious creams to life-saving medications. The journey into Polysorbate 20 begins with its fundamental nature, rooted in chemistry and innovation, and extends to its practical implementations that touch various aspects of daily life.

What is Polysorbate 20?

Polysorbate 20 is a non-ionic surfactant and emulsifier renowned for its water-soluble properties and effectiveness in stabilizing mixtures. It typically appears as a yellowish, viscous liquid, and it belongs to the polysorbate family, which includes variants like Polysorbate 40, 60, and 80. Each member of this family shares a common foundation but differs in specific fatty acid components and ethylene oxide units, tailoring them for distinct formulation needs. Polysorbate 20, in particular, is celebrated for its high hydrophilicity, making it exceptionally suited for oil-in-water emulsions. Its versatility stems from its molecular structure, which allows it to interact with both polar and non-polar substances, bridging the gap between incompatible phases. This section breaks down its origin, chemical profile, and key characteristics to provide a clear understanding of what makes Polysorbate 20 a standout ingredient in industrial applications.

Origin and Chemical Profile

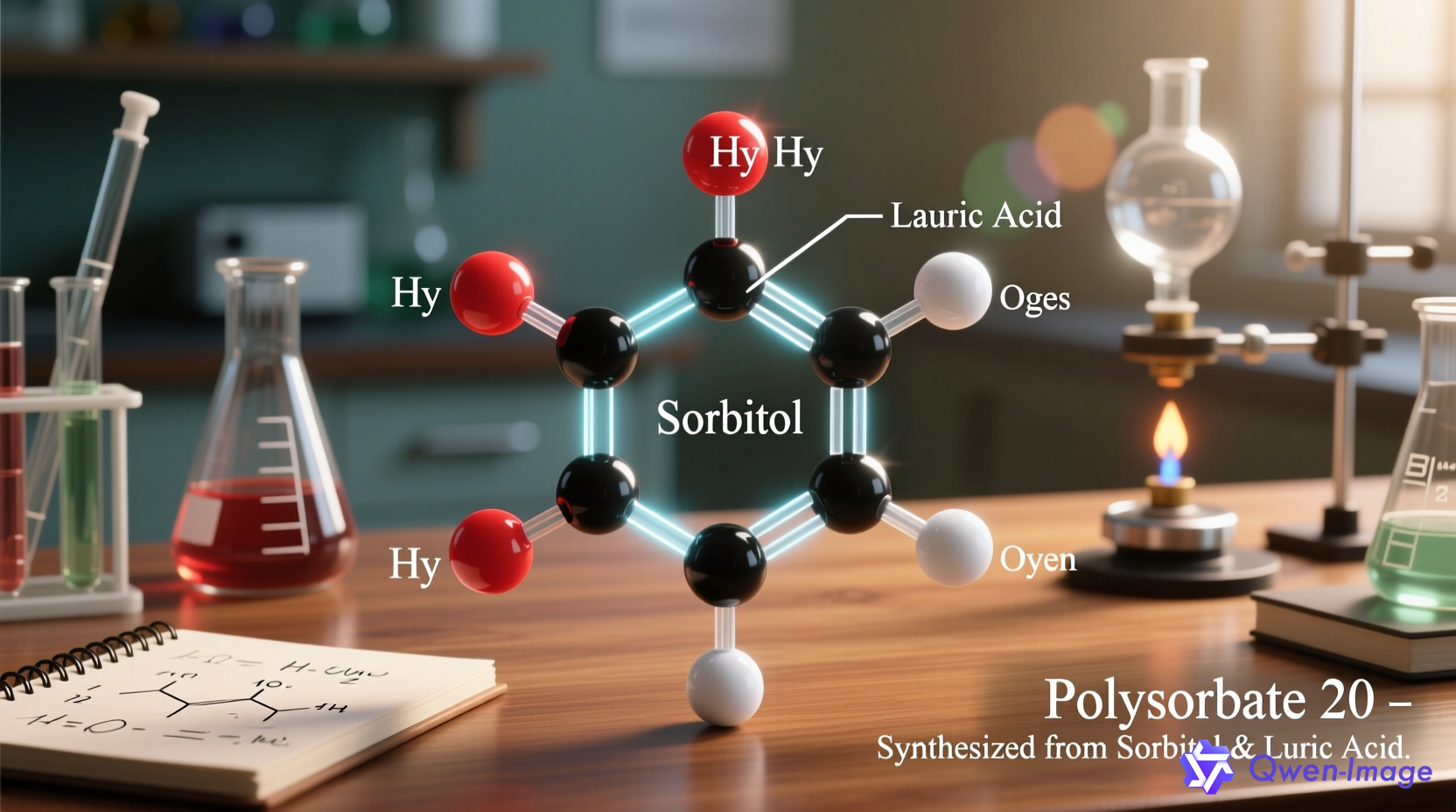

Polysorbate 20 is synthesized through the ethoxylation of sorbitan monolaurate, where sorbitol—a sugar alcohol naturally found in fruits—is esterified with lauric acid, a medium-chain fatty acid predominantly sourced from coconut oil. This derivation not only lends it a plant-based origin but also aligns with the growing demand for natural and sustainable ingredients in formulations. Chemically, it is identified as polyoxyethylene-20 sorbitan monolaurate, indicating the presence of 20 ethylene oxide units that enhance its water solubility. The production process involves careful control to ensure purity and consistency, resulting in a compound that is both effective and reliable. Historically, the development of polysorbates dates back to mid-20th century advancements in surfactant chemistry, driven by the need for better emulsifiers in emerging industries. Today, Polysorbate 20 is manufactured under strict quality standards to meet regulatory requirements, ensuring its safety and performance in various products. Its chemical profile underscores its role as a mild yet powerful agent, capable of reducing interfacial tension without introducing ionic charges that could destabilize formulations.

Key Characteristics: HLB Value and Solubility

A pivotal characteristic of Polysorbate 20 is its Hydrophile-Lipophile Balance (HLB) value, which ranges from 16 to 17. This high HLB places it firmly in the category of oil-in-water (O/W) emulsifiers, meaning it has a strong affinity for water and can effectively disperse oil phases into aqueous solutions. The HLB system, developed by Griffin, serves as a guideline for selecting emulsifiers based on their hydrophilic and lipophilic properties; values above 10 indicate a preference for water, making Polysorbate 20 ideal for formulations where water is the continuous phase. In terms of solubility, it is fully miscible with water and alcohols but only partially soluble in oils, which reinforces its role in creating clear, stable emulsions. Additionally, its non-ionic nature means it does not dissociate into ions in solution, reducing the risk of interactions with other charged ingredients and making it compatible with a wide range of compounds. This solubility profile allows it to act as a solubilizer for essential oils, fragrances, and other lipophilic substances, enabling their incorporation into water-based products without cloudiness or separation. Understanding these characteristics is crucial for formulators aiming to optimize product stability and performance, as Polysorbate 20’s properties can be leveraged to achieve desired textures, consistencies, and functional benefits.

Multifunctional Benefits of Polysorbate 20

Beyond its primary role as an emulsifier, Polysorbate 20 offers a suite of benefits that enhance product quality and user satisfaction. Its multifunctionality arises from its molecular structure, which allows it to perform various tasks simultaneously, reducing the need for additional additives and simplifying formulations. This section explores its key benefits, including emulsification, solubilization, stabilization, and more, highlighting how each contributes to superior end-products. By examining these advantages, it becomes evident why Polysorbate 20 is a preferred choice in industries where precision and reliability are paramount.

Master Emulsifier and Stabilizer

As an emulsifier, Polysorbate 20 excels at reducing the interfacial tension between oil and water, facilitating the formation of stable emulsions. This process involves adsorbing at the oil-water interface, where its hydrophilic heads orient towards water and lipophilic tails towards oil, creating a protective barrier that prevents coalescence. In practical terms, this means that products like lotions, creams, and sauces maintain a uniform texture without separating over time. Moreover, its stabilizing properties extend beyond initial mixing; it helps inhibit phase separation, creaming, or sedimentation, which are common issues in emulsions. For instance, in cosmetic formulations, it ensures that active ingredients remain evenly distributed, enhancing efficacy and shelf life. Studies have shown that emulsions stabilized with Polysorbate 20 can withstand temperature variations and mechanical stress, making them robust for storage and transport. This dual role as emulsifier and stabilizer is particularly valuable in products requiring long-term consistency, such as pharmaceuticals where dose uniformity is critical. By providing a reliable foundation, Polysorbate 20 supports the integrity of complex formulations, contributing to consumer trust and product success.

Effective Solubilizer for Oils and Fragrances

One of the standout features of Polysorbate 20 is its ability to solubilize oil-soluble ingredients in water-based systems. Solubilization involves incorporating lipophilic substances—such as essential oils, vitamins, or fragrances—into aqueous solutions to form clear, stable dispersions. This is achieved through the formation of micelles, where Polysorbate 20 molecules surround the oil droplets, allowing them to dissolve in water without precipitating. In cosmetics, this property is leveraged in products like toners, serums, and perfumes, where it enables the even distribution of aromatic compounds and active agents. For example, in a facial spray, Polysorbate 20 can solubilize essential oils to deliver soothing benefits without leaving a greasy residue. Additionally, it aids in fragrance retention by slowly releasing scents over time, enhancing the sensory experience of lotions and body sprays. In the food industry, it helps incorporate flavorings and colorings into beverages and confections, ensuring consistent taste and appearance. The effectiveness of Polysorbate 20 as a solubilizer is dose-dependent, with typical use levels of 2-10% providing optimal results without compromising safety or clarity. This benefit not only improves product aesthetics but also enhances functionality, making it a versatile tool for innovators.

Dispersing Agent and Surfactant

Polysorbate 20 also serves as a dispersing agent, ensuring that insoluble particles are uniformly distributed throughout a formulation. This is crucial in products containing pigments, powders, or other particulates, as uneven dispersion can lead to clumping, color variations, or reduced efficacy. By reducing particle aggregation, it promotes homogeneity and improves the application properties of items like mascaras, foundations, and pharmaceutical suspensions. Furthermore, its mild surfactant properties make it suitable for cleansing applications, where it helps remove dirt, oil, and impurities from surfaces without excessive drying or irritation. In skin care, it is often included in gentle cleansers and body washes, where it balances cleansing efficiency with skin compatibility. Its anti-static capabilities are another advantage, particularly in hair care products, where it minimizes static electricity that can cause frizz or discomfort. As a thickener, it can modify viscosity, enhancing the texture of lotions and creams for easier spreadability. These roles underscore its adaptability, as it can address multiple formulation challenges simultaneously. For instance, in a single product, Polysorbate 20 might emulsify oils, disperse active ingredients, and provide mild cleansing, reducing the need for complex ingredient lists. This efficiency not only streamlines production but also aligns with trends toward minimalist and multifunctional products.

Diverse Industrial Applications

The versatility of Polysorbate 20 is reflected in its widespread use across multiple industries, each leveraging its unique properties to meet specific needs. From enhancing the texture of cosmetics to ensuring the stability of pharmaceuticals, its applications are both broad and impactful. This section delves into its roles in cosmetics and personal care, the food industry, and pharmaceutical formulations, illustrating how it contributes to product innovation and safety. By examining real-world examples, we can appreciate the practical significance of Polysorbate 20 in everyday life.

In Cosmetics and Personal Care

In the cosmetics and personal care sector, Polysorbate 20 is a cornerstone ingredient found in a vast array of products, including creams, lotions, cleansers, and sprays. Its primary function here is to emulsify oil and water, creating smooth, stable formulations that deliver active ingredients effectively. For instance, in moisturizers, it ensures that oils and humectants blend seamlessly, providing hydration without greasiness. In cleansers, its surfactant properties enable gentle removal of makeup and impurities, making it ideal for sensitive skin types. Additionally, it is used in products like lipsticks and mascaras to disperse pigments evenly, enhancing color payoff and longevity. The solubilizing ability of Polysorbate 20 is particularly valued in fragrances and essential oil-based products, where it helps incorporate scents into water-based sprays without separation. A common application is in body mists, where it allows for a fine, even spray that retains fragrance over time. Safety considerations are paramount in this industry, and Polysorbate 20’s mild nature and well-established safety profile make it a reliable choice. Typical use levels range from 2% to 10%, depending on the product type, and it is often combined with other emulsifiers like sorbitan stearate to optimize performance. Overall, its role in cosmetics underscores its importance in creating products that are not only effective but also pleasurable to use.

In the Food Industry

As a food additive, Polysorbate 20 plays a critical role in improving texture, stability, and sensory attributes of various products. It is approved by regulatory bodies such as the FDA and EFSA for use in foods, where it functions as an emulsifier, stabilizer, and dispersing agent. In baked goods, for example, it helps create a soft, uniform crumb by evenly distributing fats and liquids. In dairy products like ice cream, it prevents ice crystal formation and improves melt resistance, enhancing creaminess. One notable application is in flavor emulsions, where it solubilizes oil-based flavors into water-based systems, ensuring consistent taste in beverages and candies. For instance, in mint drops or citrus-flavored drinks, Polysorbate 20 allows for a smooth, spreading sensation without oiliness. It also aids in the stabilization of colorings and vitamins, preventing sedimentation and maintaining visual appeal. The use of Polysorbate 20 in food is carefully regulated, with specified limits to ensure safety, and it is generally recognized as safe (GRAS) when used within guidelines. Its ability to enhance product quality without altering taste makes it a valuable tool for food manufacturers aiming to meet consumer demands for better texture and longevity. By supporting innovation in food science, Polysorbate 20 contributes to the development of products that are both delicious and reliable.

In Pharmaceutical Formulations

In pharmaceuticals, Polysorbate 20 is employed to enhance the stability, bioavailability, and delivery of active ingredients. Its emulsifying and solubilizing properties are crucial in oral medications, where it helps protect drugs from degradation by digestive enzymes, ensuring consistent efficacy. For example, in liquid formulations like syrups or suspensions, it prevents the separation of insoluble compounds, allowing for accurate dosing. It is also used in topical preparations, such as ointments and creams, to improve the penetration of active agents through the skin. In vaccine adjuvants and injectable formulations, Polysorbate 20 can stabilize proteins and other sensitive molecules, reducing aggregation and preserving potency. The pharmaceutical industry relies on its non-ionic nature to minimize interactions with other ingredients, which is vital for maintaining drug integrity. Safety is a top priority, and Polysorbate 20 is subject to rigorous testing and compliance with pharmacopoeial standards, such as those in the USP or EP. Typical concentrations in pharmaceuticals are tailored to specific formulations, often ranging from 0.1% to 5%, depending on the application. By facilitating reliable drug delivery, Polysorbate 20 supports patient health and treatment outcomes, highlighting its significance beyond mere formulation aids to essential components in healthcare.

Polysorbate 20 vs. Polysorbate 80: Choosing the Right Emulsifier

| roperty | Polysorbate 20 | Polysorbate 80 |

|---|---|---|

| Nom chimique | Monolaurate de polyoxyéthylène (20) sorbitane | Monooléate de polyoxyéthylène (20) sorbitane |

| CAS Number | 9005-64-5 | 9005-65-6 |

| Valeur HLB | Approximately 16.7 | Approximately 15 |

| Source | Derived from sorbitol and lauric acid | Derived from sorbitol and oleic acid |

| Apparence | Pale yellow to yellow liquid | Amber-colored, viscous liquid |

| Solubility | Soluble in water and ethanol; partially soluble in oils | Soluble in water and ethanol; more soluble in oils compared to Polysorbate 20 |

| Common Applications | Ideal for formulations with a higher water content (less than 5% oil): Facial cleansers, serums, mists | Effective in emulsifying more complex oil mixtures: Creams, lotions, ice cream |

When selecting an emulsifier, understanding the differences between Polysorbate 20 and Polysorbate 80 is essential for optimal formulation. Both are members of the polysorbate family and share similar non-ionic, emulsifying properties, but they differ in their fatty acid components and resultant characteristics. Polysorbate 20 is derived from lauric acid, giving it a higher hydrophilicity and an HLB value of 16-17, making it ideal for oil-in-water emulsions with low oil content (typically less than 5%). It excels in solubilizing essential oils and fragrances, and is often used in light products like serums, sprays, and cleansers. In contrast, Polysorbate 80, derived from oleic acid, has an HLB value of around 15 and is more versatile for higher oil content formulations, such as rich creams and cleansing oils. It offers better resistance to electrolytes and can handle a broader range of oil phases, but it may impart a slightly darker color to products. The choice between them depends on factors like oil concentration, desired clarity, and compatibility with other ingredients. For instance, in a fragrance-heavy product, Polysorbate 20 might be preferred for its superior solubilizing power, whereas in a dense lotion, Polysorbate 80 could provide better stability. Practical examples include using Polysorbate 20 in facial mists for its clarity and Polysorbate 80 in body butters for its emulsifying strength. By comparing these variants, formulators can make informed decisions to achieve specific product goals, ensuring efficiency and consumer satisfaction.

Safety and Usage Guidelines

Safety is a paramount concern when using Polysorbate 20, and extensive research supports its general recognition as safe in cosmetics, food, and pharmaceuticals. Regulatory agencies like the FDA, EFSA, and Cosmetic Ingredient Review (CIR) panel have evaluated its toxicity profile and deemed it safe for intended uses at specified concentrations. In cosmetics, it is recommended for external use only, with typical levels between 2% and 10%, though higher concentrations may be used in specific products like spray deodorants (up to 4%). While it is mild and non-irritating for most users, individuals with sensitive skin should perform patch tests to rule out allergic reactions, which are rare but possible and may include itching or redness. In food applications, it is subject to maximum usage limits to prevent overexposure, and in pharmaceuticals, it adheres to strict purity standards to avoid contaminants. The production process ensures low levels of impurities like ethylene oxide and dioxane, which are monitored to meet safety guidelines. Environmental considerations also play a role, as Polysorbate 20 is biodegradable under aerobic conditions, minimizing ecological impact. Proper handling during manufacturing includes using personal protective equipment to avoid skin or eye contact. Overall, when used as directed, Polysorbate 20 poses minimal risk and offers significant benefits, making it a trusted ingredient in global markets. Consumers and manufacturers can rely on its safety data to make informed choices, reinforcing its role in sustainable and responsible product development.

Conclusion: The Essential Role of Polysorbate 20

In summary, Polysorbate 20 stands as a multifaceted emulsifier that transcends simple mixing to enable innovation across food, cosmetics, and pharmaceuticals. Its unique chemical profile, characterized by a high HLB value and water solubility, allows it to emulsify, solubilize, stabilize, and disperse with remarkable efficiency. From creating luxurious creams that feel smooth on the skin to ensuring medications deliver consistent doses, its applications are both diverse and critical. The comparison with Polysorbate 80 highlights the importance of tailored selection in formulation, while safety guidelines provide assurance for its widespread use. As industries evolve toward more natural and sustainable practices, Polysorbate 20’s plant-based origin positions it as a forward-thinking choice. For those seeking reliable ingredients, FoodEmul.com offers high-quality Polysorbate 20 and related products, supporting excellence in formulation. Ultimately, Polysorbate 20 is not just an additive but a key enabler of product quality, safety, and consumer satisfaction, underscoring its enduring relevance in a dynamic market.

| roperty | Polysorbate 20 | Polysorbate 80 |

|---|---|---|

| Nom chimique | Monolaurate de polyoxyéthylène (20) sorbitane | Monooléate de polyoxyéthylène (20) sorbitane |

| CAS Number | 9005-64-5 | 9005-65-6 |

| Valeur HLB | Approximately 16.7 | Approximately 15 |

| Source | Derived from sorbitol and lauric acid | Derived from sorbitol and oleic acid |

| Apparence | Pale yellow to yellow liquid | Amber-colored, viscous liquid |

| Solubility | Soluble in water and ethanol; partially soluble in oils | Soluble in water and ethanol; more soluble in oils compared to Polysorbate 20 |

| Common Applications | Ideal for formulations with a higher water content (less than 5% oil): Facial cleansers, serums, mists | Effective in emulsifying more complex oil mixtures: Creams, lotions, ice cream |