Introduction to Polysorbate 80

In the realm of modern product formulation, achieving stability, consistency, and appeal in mixtures of oil and water is a fundamental challenge. Polysorbate 80, a powerful nonionic surfactant and emulsifier, stands out as a versatile ingredient that addresses this challenge across diverse industries. Derived from polyethoxylated sorbitan and oleic acid, this compound is a viscous, water-soluble liquid known for its ability to create stable emulsions. From ensuring the creamy texture of ice cream to stabilizing life-saving vaccines and enhancing the smoothness of cosmetic creams, Polysorbate 80 plays an indispensable yet often overlooked role. This article delves into the chemistry, functions, applications, and safety considerations of Polysorbate 80, providing a comprehensive overview for manufacturers, formulators, and curious consumers. By understanding its multifaceted nature, we can appreciate how this emulsifier contributes to the quality and longevity of everyday products.

What is Polysorbate 80?

Polysorbate 80 is a synthetic emulsifier and surfactant classified as a nonionic compound due to its lack of electrical charge. It is chemically derived from sorbitol and oleic acid, resulting in a structure that includes hydrophilic polyoxyethylene groups and a lipophilic oleic acid tail. This amphiphilic nature allows it to interact with both water and oil, making it highly effective in reducing surface tension and stabilizing mixtures. The “80” in its name specifically refers to the oleic acid fatty acid chain, distinguishing it from other polysorbates like Polysorbate 20 (with lauric acid) or Polysorbate 60 (with stearic acid). In its pure form, Polysorbate 80 appears as a viscous, yellow-to-amber liquid that is soluble in water, ethanol, and various oils. Its molecular formula and structure contribute to its low critical micelle concentration (CMC) of approximately 0.012 mM, meaning it can form stable micelles and emulsions even at low concentrations. This efficiency is why it is widely used in food, pharmaceutical, and cosmetic formulations, often under brand names such as Tween 80, Kolliphor PS 80, and Montanox 80. Understanding its basic composition is key to leveraging its benefits in various applications.

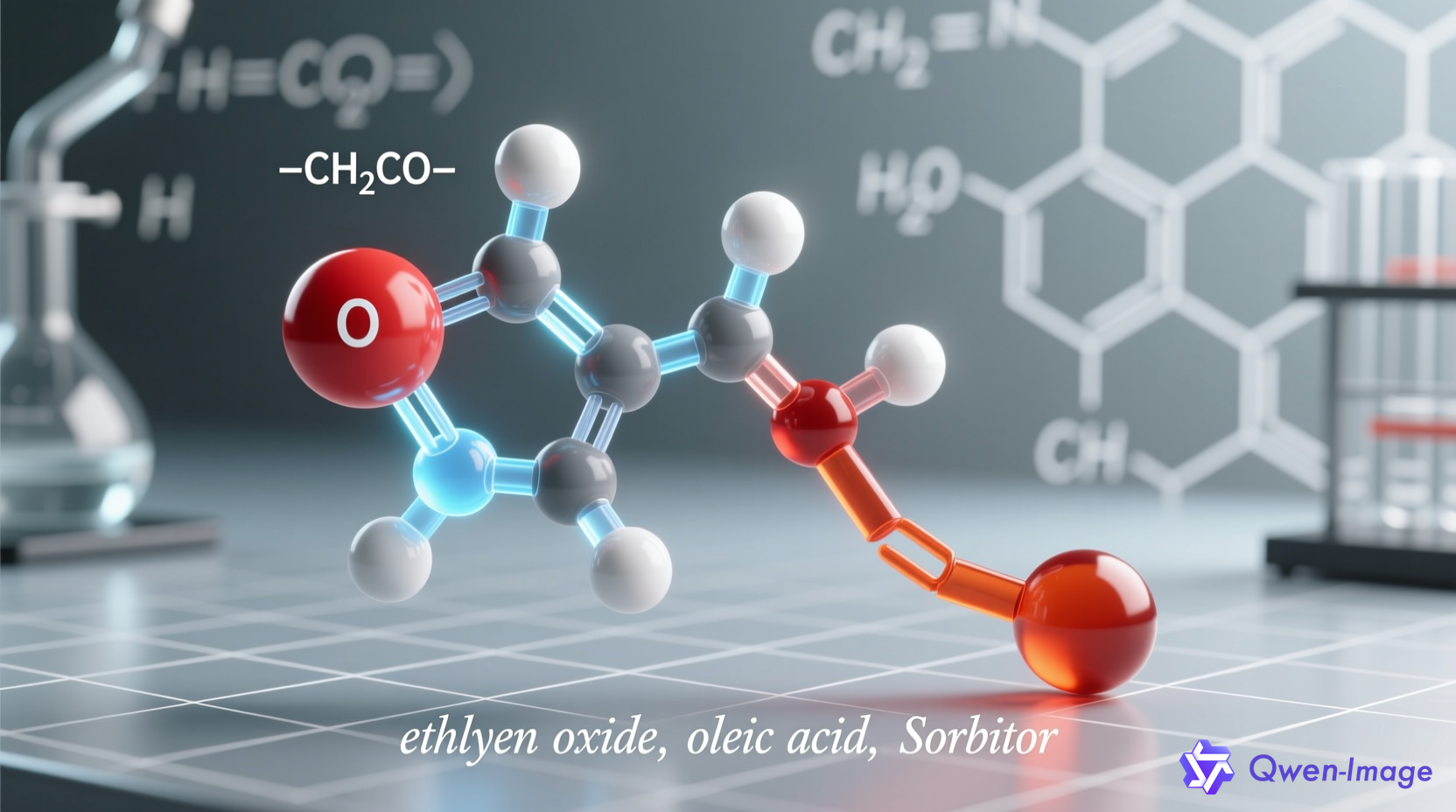

The Chemistry Behind Polysorbate 80

The chemical identity of Polysorbate 80 is defined as polyoxyethylene (20) sorbitan monooleate, where the number 20 indicates the average number of oxyethylene units in the hydrophilic chain. This structure is achieved through the ethoxylation of sorbitan esters derived from sorbitol, a sugar alcohol, followed by esterification with oleic acid. The oleic acid component, a monounsaturated omega-9 fatty acid, provides the lipophilic properties, while the polyoxyethylene chain offers hydrophilicity. This balance enables Polysorbate 80 to act as an effective emulsifier by positioning itself at the interface between oil and water phases, reducing interfacial tension and preventing coalescence. In aqueous solutions, it forms micelles—aggregates where the hydrophobic tails cluster inward and hydrophilic heads face outward—facilitating the solubilization of oils and other non-polar substances. The compound’s viscosity and solubility profile (soluble in water, ethanol, cottonseed oil, and other solvents) make it adaptable to various formulations. Moreover, its nonionic nature means it is less likely to interact with ionic compounds, reducing the risk of precipitation or instability in complex mixtures. This chemical robustness underpins its widespread use and reliability in industrial applications.

Polysorbate 80 vs. Other Polysorbates

Polysorbates are a family of emulsifiers that share a common sorbitan backbone but differ in their fatty acid chains, leading to variations in properties and applications. The numeric suffix (e.g., 20, 40, 60, 80) denotes the specific fatty acid: Polysorbate 20 uses lauric acid, Polysorbate 40 uses palmitic acid, Polysorbate 60 uses stearic acid, and Polysorbate 80 uses oleic acid. These differences influence factors like hydrophile-lipophile balance (HLB), solubility, and emulsification efficiency. For instance, Polysorbate 20, with its shorter lauric acid chain, has a higher HLB value and is more water-soluble, making it suitable for oil-in-water emulsions in products like mouthwashes and fragrances. In contrast, Polysorbate 80, with its oleic acid chain, has a moderate HLB and excels in stabilizing emulsions where a balance between oil and water solubility is needed, such as in ice cream or pharmaceutical injections. The choice of polysorbate depends on the specific requirements of the formulation, including the type of emulsion, desired texture, and compatibility with other ingredients. By comparing these variants, formulators can select the most appropriate emulsifier to achieve optimal product performance and stability.

Key Functions and Benefits of Polysorbate 80

Polysorbate 80 offers a range of functional benefits that make it invaluable in product development. Its primary role is emulsification, where it stabilizes mixtures of immiscible liquids like oil and water by forming a protective layer around dispersed droplets. This prevents separation and ensures uniformity throughout the product’s shelf life. Additionally, it acts as a surfactant, reducing surface tension to improve wetting, spreading, and dispersion in various systems. In terms of texture enhancement, Polysorbate 80 contributes to smoother, creamier consistencies in foods and cosmetics, often improving mouthfeel and application properties. It also serves as a solubilizer, enabling the incorporation of oils, fragrances, and active ingredients into aqueous solutions, which is crucial in pharmaceuticals and personal care products. Beyond these core functions, it can enhance foaming and aeration in products like ice cream, leading to lighter textures and improved volume. The benefits extend to preservation, as stable emulsions reduce spoilage risks by minimizing ingredient separation and crystallization. Overall, Polysorbate 80’s multifunctionality supports product quality, consistency, and consumer satisfaction across industries.

Superior Emulsification and Stabilization

Emulsification is the cornerstone of Polysorbate 80’s functionality, driven by its amphiphilic structure that allows it to bridge hydrophobic and hydrophilic phases. In practical terms, when added to a mixture like salad dressing or ice cream, it positions itself at the oil-water interface, lowering the interfacial tension and forming small, stable droplets that resist coalescence. This process creates homogeneous emulsions that remain uniform over time, preventing issues like oil separation or sedimentation. The stabilization effect is further enhanced by its ability to form micelles, which can encapsulate oil-soluble components and keep them dispersed in water-based systems. This is particularly important in products requiring long shelf lives, as it maintains aesthetic appeal and functional integrity. For example, in ice cream, Polysorbate 80 prevents milk proteins from fully coating fat droplets, allowing them to form networks that trap air and provide a firm, smooth texture. Similarly, in pharmaceuticals, it stabilizes emulsions in injectable drugs, ensuring consistent dosing and efficacy. The efficiency of Polysorbate 80 in emulsification and stabilization makes it a preferred choice for formulators seeking reliable performance in diverse applications.

Enhancing Texture and Mouthfeel

Texture and mouthfeel are critical sensory attributes in consumer products, and Polysorbate 80 plays a key role in their enhancement. In food applications, it imparts a creamy, smooth consistency by controlling crystallization and improving dispersion. For instance, in ice cream, it inhibits the formation of large ice crystals, resulting in a softer, more luxurious texture that melts evenly. In baked goods, it increases dough elasticity and volume, leading to lighter, moister products that resist staling. The emulsifier also improves the mouthfeel of beverages and sauces by ensuring even distribution of fats and flavors, avoiding grittiness or oiliness. In cosmetics, Polysorbate 80 contributes to the silky, non-greasy feel of lotions and creams, enhancing user experience through better spreadability and absorption. These textural improvements are not merely cosmetic; they influence consumer perception and preference, driving repeat purchases. By optimizing the physical properties of products, Polysorbate 80 helps manufacturers meet expectations for quality and pleasure, whether in a decadent dessert or a daily skincare routine.

Solubilization and Dispersion

Solubilization and dispersion are essential functions of Polysorbate 80, particularly in systems where oil-soluble ingredients need to be incorporated into water-based formulations. As a solubilizer, it forms micelles that can encapsulate hydrophobic compounds like essential oils, vitamins, or drugs, allowing them to dissolve in aqueous environments. This is vital in pharmaceuticals, where it enables the formulation of stable injectables and oral suspensions by preventing precipitation or aggregation of active ingredients. In cosmetics, it helps disperse fragrances and oils evenly in lotions, ensuring consistent scent and efficacy. The dispersion capability also applies to food products; for example, in chocolate drinks, Polysorbate 80 keeps cocoa butter uniformly mixed, preventing separation and ensuring a smooth, consistent beverage. This function extends to industrial applications, such as in paints and cleaners, where it aids in the even distribution of pigments and agents. The ability of Polysorbate 80 to enhance solubility and dispersion not only improves product performance but also expands formulation possibilities, allowing for innovative and complex mixtures that would otherwise be unstable.

Applications of Polysorbate 80 Across Industries

Polysorbate 80 finds extensive use in multiple sectors due to its versatility and efficacy. In the food industry, it is employed as a food-grade emulsifier (E433) to improve texture, consistency, and shelf life in products like ice cream, baked goods, and dressings. The pharmaceutical industry relies on high-purity grades for stabilizing vaccines, drugs, and injectables, ensuring safety and potency. In cosmetics and personal care, it enhances the smoothness and stability of creams, lotions, and makeup. Beyond these, it is used in laboratory settings for microbial culture media and in industrial applications like paints and cleaners. Each industry benefits from Polysorbate 80’s ability to create stable emulsions, solubilize ingredients, and enhance product qualities, making it a cornerstone of modern manufacturing. The following sections explore these applications in detail, highlighting specific examples and benefits.

In the Food Industry (Food Grade)

In the food sector, Polysorbate 80 is valued for its role in enhancing product quality and consumer appeal. As an approved food additive (E433), it is used in various products to prevent separation, improve texture, and extend shelf life. For example, in ice cream, it is added at concentrations up to 0.5% to create a smoother, creamier consistency by inhibiting ice crystal formation and increasing resistance to melting. This is achieved by modifying the behavior of milk proteins and fat droplets, allowing them to form stable networks that incorporate air. In baked goods, such as bread and cakes, Polysorbate 80 improves dough handling, increases volume, and retains moisture, resulting in softer, fresher products. Salad dressings and sauces benefit from its emulsifying properties, which maintain a homogeneous mixture of oil and vinegar, preventing unsightly separation. Additionally, in chocolate and powdered drinks, it ensures even dispersion of cocoa butter, enhancing mouthfeel and consistency. Other applications include chewing gum, where it softens texture and prolongs flavor release, and custards or puddings, where it stabilizes against syneresis (water separation). The use of food-grade Polysorbate 80, which meets strict purity standards, ensures safety and compliance with regulatory limits, such as the acceptable daily intake (ADI) of 25 mg/kg body weight. By addressing common formulation challenges, it enables the production of high-quality, stable food products that meet consumer demands for taste and texture.

In Pharmaceuticals

The pharmaceutical industry utilizes Polysorbate 80 in various formulations due to its stabilizing and solubilizing properties. High-purity grades are essential for ensuring the safety and efficacy of medications, particularly in parenteral (injectable) products. For instance, it is used as an excipient in vaccines, including influenza and COVID-19 vaccines, to stabilize active ingredients and prevent aggregation, thereby maintaining potency during storage and administration. In injectable drugs, such as amiodarone for arrhythmia, Polysorbate 80 helps solubilize lipophilic compounds, allowing for consistent dosing and reduced risk of adverse reactions. Oral liquids, like syrups and suspensions, also incorporate it to ensure uniform distribution of active components, improving bioavailability and patient compliance. Beyond drug formulations, Polysorbate 80 is employed in laboratory settings, such as in Middlebrook 7H9 broth for culturing Mycobacterium tuberculosis, where it acts as a surfactant to promote microbial growth. Its role in pharmaceuticals underscores the importance of emulsifiers in enhancing drug delivery and stability, contributing to public health by supporting reliable and effective treatments.

In Cosmetics and Personal Care

In cosmetics and personal care products, Polysorbate 80 serves as a key ingredient for achieving desirable textures and stability. It is commonly found in creams, lotions, serums, and makeup, where it functions as an emulsifier to blend oil and water-based components, preventing separation and ensuring a smooth, uniform application. For example, in moisturizers, it helps create a non-greasy, easily absorbable formula that leaves skin feeling soft and hydrated. In makeup products like foundations and lipsticks, it improves spreadability and longevity, enhancing user experience. Polysorbate 80 is also used in cleansers and soaps to aid in the removal of oils and impurities, thanks to its surfactant properties. While cosmetic-grade versions may have different purity standards compared to food or pharmaceutical grades, they still provide effective performance in personal care formulations. Additionally, it can act as a solubilizer for fragrances and essential oils, ensuring even distribution and consistent scent in products like perfumes and body sprays. By contributing to product stability and sensory qualities, Polysorbate 80 helps cosmetic brands deliver high-quality items that meet consumer expectations for efficacy and pleasure.

Safety, Regulations, and Considerations

The safety of Polysorbate 80 is well-established through regulatory approvals and scientific research, but it is important to understand the guidelines and potential considerations. Globally, it is approved by authorities such as the U.S. Food and Drug Administration (FDA), the European Food Safety Authority (EFSA), and others, with an acceptable daily intake (ADI) set at 25 mg per kilogram of body weight. This ADI is based on extensive toxicological studies and far exceeds typical exposure levels from food and products. However, some research, primarily in animal models, has suggested that high doses of emulsifiers like Polysorbate 80 might impact gut microbiota, potentially leading to inflammation or metabolic issues. It is crucial to note that these studies often use concentrations not representative of normal human consumption, and more research is needed in humans. For most people, Polysorbate 80 is considered safe when used within regulatory limits. In terms of regulations, different grades (food, pharmaceutical, cosmetic) have specific purity requirements to ensure safety for their intended uses. Consumers with sensitivities or allergies should check product labels, as rare reactions like skin rashes or gastrointestinal discomfort have been reported. Overall, adherence to guidelines and informed usage ensures that Polysorbate 80 continues to be a beneficial ingredient in various applications.

Regulatory Approval and ADI

Polysorbate 80 has received widespread regulatory approval for use in food, pharmaceuticals, and cosmetics. In the food industry, it is designated as E433 in the European Union and is generally recognized as safe (GRAS) by the FDA in the United States. The acceptable daily intake (ADI) of 25 mg/kg body weight, established by bodies like the Joint FAO/WHO Expert Committee on Food Additives (JECFA), provides a safety margin that accounts for lifetime exposure without adverse effects. This ADI is derived from animal studies where no observed adverse effect levels (NOAELs) were identified, and it is significantly higher than the amounts typically consumed through processed foods. For pharmaceuticals, Polysorbate 80 must meet compendial standards such as those in the U.S. Pharmacopeia (USP) or European Pharmacopoeia (Ph. Eur.), ensuring high purity and minimal impurities. Cosmetic regulations, like those under the FDA or EU cosmetics regulation, also specify allowable concentrations and purity grades. These regulatory frameworks ensure that Polysorbate 80 is used safely across industries, with ongoing monitoring and updates based on new scientific evidence. By complying with these standards, manufacturers can confidently incorporate Polysorbate 80 into their products, knowing it meets rigorous safety criteria.

Health and Safety Discussion

While Polysorbate 80 is generally safe, some health considerations have emerged from scientific studies, particularly regarding gut health. Research in animal models, such as mice, has shown that high doses of emulsifiers can alter the composition of gut microbiota, potentially increasing intestinal permeability and promoting conditions like inflammatory bowel disease (IBD) or metabolic syndrome. For example, a 2021 study published in Microbiome indicated that dietary emulsifiers might directly impact human gut microbes, but these findings are preliminary and not yet confirmed in large-scale human trials. It is important to contextualize these results: the doses used in such studies are often much higher than what humans would consume through a balanced diet, and individual factors like genetics and overall diet play a role. For the vast majority of consumers, the benefits of Polysorbate 80 in ensuring product stability and quality outweigh potential risks, especially when intake remains within the ADI. Additionally, rare allergic reactions or sensitivities can occur, manifesting as skin irritation or digestive issues, so individuals with known allergies should avoid products containing this additive. Overall, the consensus among regulatory bodies is that Polysorbate 80 is safe for its intended uses, but ongoing research and consumer awareness are encouraged to ensure informed choices.

Conclusion: An Indispensable Ingredient for Modern Formulations

Polysorbate 80 has proven to be a cornerstone of innovation in food, pharmaceutical, and cosmetic industries, thanks to its exceptional emulsifying, stabilizing, and texturizing properties. From creating creamy ice creams and stable salad dressings to ensuring the efficacy of vaccines and the smoothness of lotions, its versatility addresses key challenges in product development. While safety considerations exist, particularly in the context of high-dose exposures, regulatory approvals and the established ADI provide a robust framework for its safe use. As consumer preferences evolve towards clean-label and natural alternatives, the role of synthetic emulsifiers like Polysorbate 80 may be complemented by options like lecithin or gums, but its efficiency and reliability ensure it remains a vital tool for formulators. By leveraging Polysorbate 80, manufacturers can achieve superior product quality, consistency, and consumer satisfaction, driving advancements across multiple sectors. For those seeking high-quality emulsifiers, exploring specialized suppliers can open doors to innovative applications and enhanced formulations.

At FoodEmul.com, we specialize in providing premium sorbitan esters and polysorbates, including Polysorbate 80, tailored to your formulation needs. Whether you are developing food products, pharmaceuticals, or cosmetics, our range offers reliable solutions for emulsification and stability. Visit our product catalog to discover how our ingredients can elevate your next project and meet the highest standards of quality and safety.