Introduction to the Versatile World of Polysorbates

Polysorbates are a class of non-ionic surfactants and emulsifiers that play a pivotal role in modern manufacturing across the food, cosmetics, and pharmaceutical industries. Derived from natural sources such as sorbitol and specific fatty acids, these compounds are essential for creating stable, high-quality products that meet consumer demands for consistency and performance. As oily, water-soluble liquids, polysorbates like Tween 20, 40, 60, and 80 are renowned for their ability to blend immiscible ingredients, prevent separation, and enhance texture. This guide delves into the unique characteristics and applications of each type, providing a thorough understanding of how these emulsifiers can benefit various formulations. Whether you are developing a new food product, a cosmetic item, or a pharmaceutical solution, polysorbates offer reliable solutions for emulsification, solubilization, and stabilization. By exploring their scientific foundations and practical uses, this article aims to equip industry professionals with the knowledge to make informed decisions about incorporating polysorbates into their products.

What Are Polysorbates? The Science Made Simple

Chemical Structure and Origin

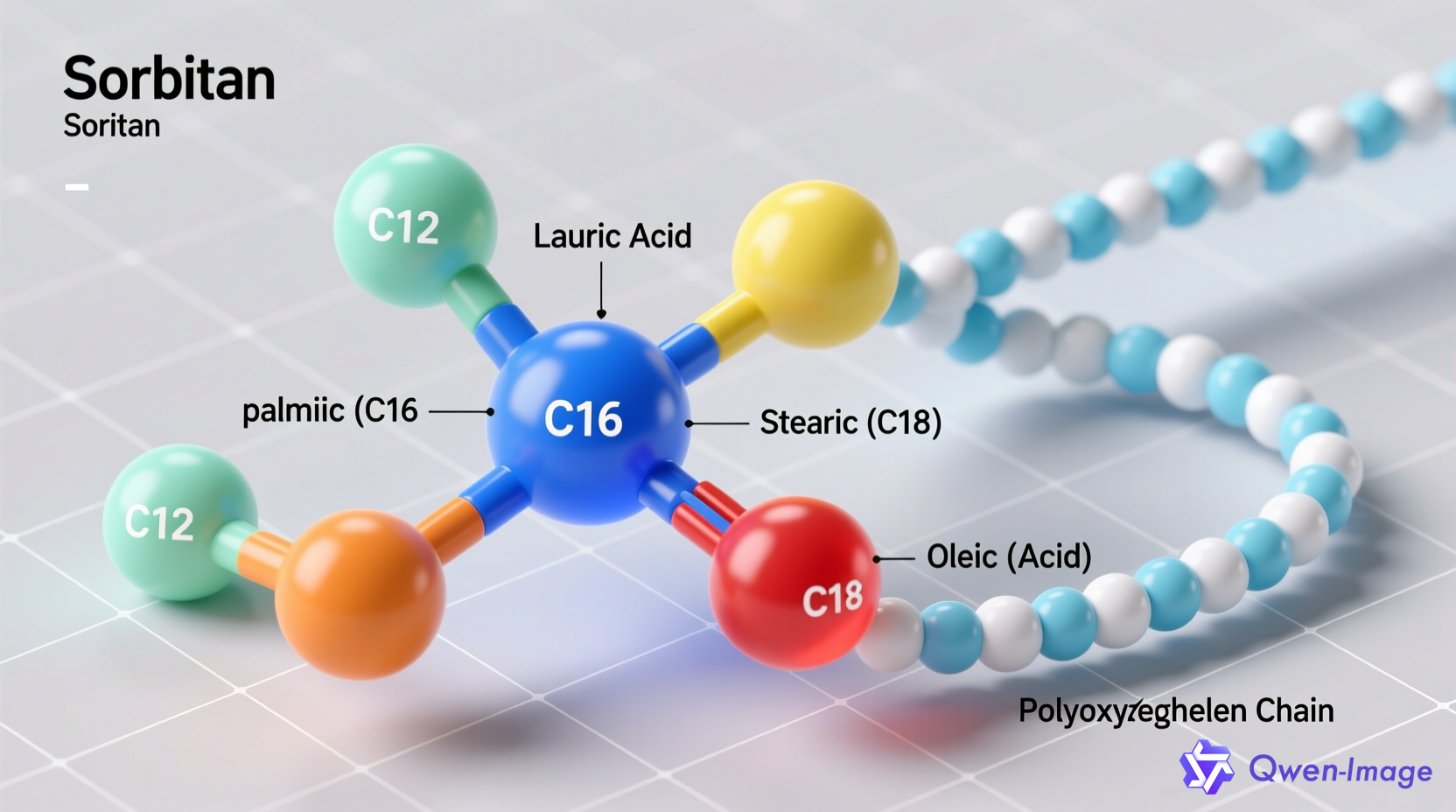

Polysorbates are synthesized through a multi-step process that begins with sorbitol, a sugar alcohol derived from natural sources like corn or wheat. Through dehydration, sorbitol is converted into sorbitan, which is then ethoxylated by reacting with ethylene oxide to form polyoxyethylene sorbitan. This intermediate is further esterified with specific fatty acids, resulting in the final polysorbate compound. The chemical structure consists of a sorbitan backbone attached to fatty acid chains and polyoxyethylene groups, which impart hydrophilic (water-loving) and lipophilic (oil-loving) properties. This amphiphilic nature allows polysorbates to act as effective surfactants, reducing surface tension and facilitating the mixing of oil and water phases. Typically, polysorbates exist as viscous, amber to yellow liquids, and their non-ionic character makes them compatible with a wide range of ingredients without causing irritation or instability. Understanding this molecular foundation is crucial for appreciating how polysorbates function in diverse applications, from food emulsions to pharmaceutical suspensions.

Decoding the Numbers: 20, 40, 60, and 80

The numerical designations in polysorbate names—20, 40, 60, and 80—correspond to the type of fatty acid esterified to the polyoxyethylene sorbitan core. Specifically, Polysorbate 20 uses lauric acid, Polysorbate 40 employs palmitic acid, Polysorbate 60 incorporates stearic acid, and Polysorbate 80 features oleic acid. Additionally, the ‘polyoxyethylene (20)’ part indicates that each molecule contains approximately 20 oxyethylene groups, which contribute to the hydrophilic-lipophilic balance (HLB) and solubility characteristics. This numbering system simplifies identification and selection based on the desired fatty acid profile, which influences properties like melting point, solubility, and emulsifying efficiency. For instance, lauric acid in Tween 20 results in a lower molecular weight and higher water solubility, making it ideal for mild applications, while oleic acid in Tween 80 offers better oil compatibility and is commonly used in food products. By decoding these numbers, formulators can quickly assess which polysorbate variant best suits their needs, whether for creating stable emulsions in cosmetics or improving texture in baked goods.

Deep Dive into Key Polysorbates and Their Applications

| Name | Chemical Name | Fatty Acid Source | HLB Value (Approx.) | Physical Appearance | Main Applications | Key Properties | Food Additive Code | Safety & Regulatory Status |

|---|---|---|---|---|---|---|---|---|

| Polissorbato 20 | Polyoxyethylene (20) sorbitan monolaurate | Lauric acid (C12) | ~16.7 | Clear to light yellow liquid | - Cosmetics: solubilizer for essential oils - Pharma: stabilizer in emulsions & suspensions - Biotech: washing agent, protein solubilizer - Food: flavor emulsifier | - Excellent wetting agent - Stable & nontoxic - Good solubilizing capacity | E432 | Evaluated as safe by CIR & FDA; non-toxic, widely used in cosmetics and food |

| Polysorbate 40 | Polyoxyethylene (20) sorbitan monopalmitate | Palmitic acid (C16) | ~15.6 | Yellowish oily liquid | - Food emulsifier - Cosmetics and pharmaceuticals - Industrial formulations | - Medium HLB; balances oil/water emulsions - Improves texture and stability | E434 | Approved by FDA & EFSA as safe food additive |

| Polissorbato 60 | Polyoxyethylene (20) sorbitan monostearate | Stearic acid (C18) | ~14.9 | Pale-yellow to amber viscous liquid | - Food: emulsifier for baked goods, desserts - Cosmetics: lotions, creams, shampoos - Industrial: surfactant in detergents | - Synthetic emulsifier - Extends shelf life of baked goods - Enhances texture & volume | E435 | Approved by FDA, EFSA, JECFA; considered safe |

| Polissorbato 80 | Polyoxyethylene (20) sorbitan monooleate | Oleic acid (C18:1) | ~15.0 | Amber/golden viscous liquid | - Food: salad dressings, chocolates, ice cream - Pharma: solubilizer for active ingredients - Cosmetics: disperses oils & pigments | - High solubility - Improves smoothness, melt resistance - Non-ionic surfactant with broad use | E433 | FDA, EFSA, and WHO approved; non-GMO, vegetable-derived |

Polysorbate 20 (Tween 20): The Gentle Solubilizer

Polysorbate 20, commercially known as Tween 20, is derived from lauric acid and is characterized by its mild surfactant properties and high solubility in water. With an HLB value around 16.7, it excels as a solubilizer and wetting agent, making it a preferred choice in cosmetics for incorporating essential oils, fragrances, and colorants into water-based formulations like lotions, shampoos, and facial cleansers. In the pharmaceutical industry, Tween 20 is invaluable for stabilizing emulsions and suspensions, as well as in biochemical applications such as immunoassays and cell lysis, where it helps solubilize membrane proteins without denaturing them. Its low toxicity and stability under various conditions further enhance its appeal, with regulatory bodies like the Cosmetic Ingredient Review (CIR) affirming its safety for topical use. In food applications, it serves as a wetting agent in flavored mouth drops, ensuring even distribution of ingredients and a pleasant mouthfeel. Overall, Polysorbate 20’s versatility and gentle nature make it a cornerstone in products requiring precise solubilization and minimal irritation.

Polysorbate 80 (Tween 80): The All-Rounder Emulsifier

Polysorbate 80, or Tween 80, is formulated with oleic acid and boasts an HLB value of approximately 15, positioning it as a highly effective emulsifier for a broad spectrum of applications. Its ability to dissolve solid ingredients and create stable oil-in-water emulsions makes it indispensable in the food industry, particularly in ice cream production, where it imparts a smooth texture, reduces ice crystal formation, and enhances melt resistance at concentrations up to 0.5%. Similarly, in salad dressings and chocolates, it prevents separation and ensures a consistent product. In cosmetics, Tween 80 is used to blend oils and water in skin cleansers, hair care products, and makeup, while in pharmaceuticals, it acts as a dispersing agent for active ingredients in tablets and supplements. Sourced from vegetable origins and free from genetically modified organisms, it aligns with consumer preferences for natural and safe ingredients. Its amber color and viscous consistency do not compromise functionality, and its approval by agencies like the FDA and EFSA underscores its reliability. Polysorbate 80’s all-round capabilities make it a go-to emulsifier for formulators seeking versatility and performance across industries.

Polysorbate 60 (Tween 60): The Bakery and Personal Care Specialist

Polysorbate 60, known as Tween 60, is synthesized from stearic acid and features an HLB value of about 14.9, making it particularly effective in bakery and personal care products. In the food sector, it is widely used to improve the volume, texture, and shelf life of baked goods like bread, cakes, and frozen desserts by ensuring even distribution of fats and moisture. As an emulsifier, it prevents oil and water separation, contributing to a soft crumb and extended freshness. In cosmetics, Tween 60 serves as a surfactant, emulsifier, and dispersing agent in lotions, creams, shampoos, and makeup, helping to evenly distribute fragrances, essential oils, and colorants while enhancing cleansing action by reducing surface tension on the skin. Often blended with low-HLB emulsifiers like sorbitan stearate, it allows for customized HLB values to suit specific emulsion types, whether oil-in-water or water-in-oil. Approved by regulatory authorities such as the FDA, EFSA, and JECFA, Polysorbate 60 is recognized as safe for consumption and topical use, solidifying its role as a specialist in applications where stability and texture are paramount.

Why Choose Polysorbates? Key Functional Benefits

Superior Emulsification and Stability

One of the primary reasons for selecting polysorbates is their exceptional ability to create and maintain stable emulsions. By reducing the interfacial tension between oil and water phases, polysorbates prevent coalescence and separation, resulting in homogeneous products that retain their integrity over time. In food items like mayonnaise and salad dressings, this ensures a creamy consistency and prolonged shelf life, while in cosmetics such as moisturizers and foundations, it guarantees a smooth application and even coverage. The non-ionic nature of polysorbates allows them to function effectively across a wide pH range and in the presence of electrolytes, making them suitable for diverse formulations. Additionally, their compatibility with other emulsifiers enables synergistic effects, enhancing overall stability without compromising sensory attributes. This emulsifying prowess is backed by decades of industrial use, demonstrating that polysorbates consistently deliver reliable performance in preventing phase separation and improving product quality.

Effective Solubilization and Dispersion

Polysorbates excel at solubilizing hydrophobic substances like oils, fragrances, and active ingredients into aqueous systems, ensuring uniform distribution and enhanced bioavailability. This property is crucial in pharmaceuticals, where polysorbates help dissolve poorly soluble drugs, improving their efficacy and stability in formulations such as injections and oral suspensions. In cosmetics, they enable the incorporation of essential oils and colorants into water-based products, resulting in vibrant, long-lasting effects without sedimentation. The solubilization process involves the formation of micelles, where the lipophilic parts of polysorbates encapsulate oil droplets, allowing them to disperse evenly in water. This not only improves product aesthetics but also enhances functionality, as in the case of shampoos and body washes, where polysorbates aid in washing away dirt and oils by lowering surface tension. By facilitating the dissolution and dispersion of challenging ingredients, polysorbates contribute to more efficient and effective product development across sectors.

Enhanced Product Texture and Performance

Beyond emulsification and solubilization, polysorbates significantly improve the texture, mouthfeel, and overall performance of end products. In food applications, they contribute to a smoother, creamier consistency in ice cream, prevent staling in baked goods, and enhance the spreadability of confectioneries. For instance, the use of Polysorbate 80 in ice cream reduces iciness and improves scoopability, while Polysorbate 60 in bread increases volume and softness. In cosmetics, polysorbates impart a non-greasy feel to lotions and creams, improve the lathering action of cleansers, and ensure even color payoff in makeup. Their ability to modify rheological properties also aids in processing efficiency, such as easier pumping and mixing during manufacturing. These enhancements not only meet consumer expectations for quality but also extend product lifespan, reducing waste and increasing satisfaction. By optimizing texture and performance, polysorbates add tangible value to formulations, making them indispensable in competitive markets.

Safety and Regulatory Compliance of Polysorbates

Polysorbates are subject to rigorous safety evaluations and are generally recognized as safe by major regulatory bodies worldwide, including the U.S. Food and Drug Administration (FDA), the European Food Safety Authority (EFSA), and the Joint FAO/WHO Expert Committee on Food Additives (JECFA). Extensive toxicological studies have confirmed that, when used within recommended limits, polysorbates pose minimal risk to human health in food, cosmetic, and pharmaceutical applications. For example, the Cosmetic Ingredient Review (CIR) has assessed polysorbates like Tween 20 and Tween 60 and deemed them safe for topical use, citing low irritation potential and favorable safety profiles. In food, polysorbates are assigned E numbers (e.g., E433 for Polysorbate 80) and are approved for use in various products, with specified maximum usage levels to ensure consumer safety. Additionally, many polysorbates are derived from non-GMO vegetable sources, aligning with trends toward natural and sustainable ingredients. By adhering to these regulatory guidelines, manufacturers can confidently incorporate polysorbates into their formulations, knowing they meet high standards of safety and compliance.

Conclusion: Partner with FoodEmul.com for Your Emulsifier Needs

In summary, polysorbate emulsifiers such as Tween 20, 40, 60, and 80 offer unparalleled benefits in terms of emulsification, solubilization, and product enhancement across the food, cosmetics, and pharmaceutical industries. Each variant brings unique properties tailored to specific applications, from the gentle solubilizing action of Polysorbate 20 to the all-round emulsifying capabilities of Polysorbate 80 and the specialized uses of Polysorbate 60 in bakery and personal care. Their safety and regulatory approval further underscore their reliability as ingredients of choice. At FoodEmul.com, we are committed to providing high-quality, food-grade polysorbates and sorbitan esters, backed by expert support to help you select the ideal emulsifier for your formulation challenges. Whether you are developing a new product or optimizing an existing one, our team is here to assist with technical guidance and reliable supply. Embrace the versatility of polysorbates and elevate your products with the trusted solutions from FoodEmul.com.