Overview

-

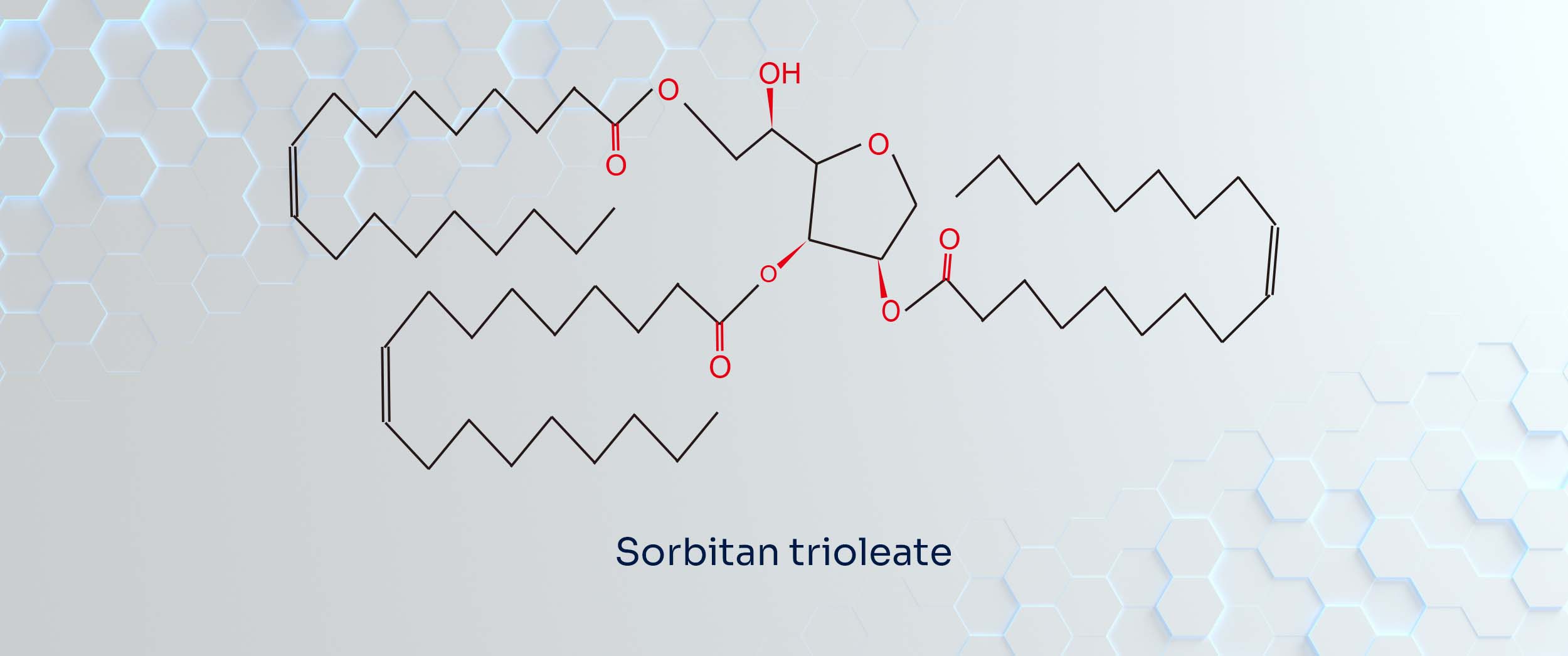

Chemical NatureSpecialized non-ionic surfactant consisting of sorbitan esterified with three oleic acid chains.

-

Appearance & SpecsViscous amber liquid | HLB Value: 1.8

-

★ Primary Application (Industrial/Energy)Critical Additive for Harsh Conditions. Highly lipophilic. Essential in the energy sector for oil drilling fluids and emulsion explosives to stabilize W/O systems.

-

Cosmetics UseEffective pigment dispersant in anhydrous (water-free) cosmetics.

-

Key FunctionsUltra-Low HLB Oil Dispersant.

Molecular Structure

-

Structural ComponentsHydrophilic Core: Sorbitan backbone.Hydrophobic Moiety: Three oleic acid residues esterified to the backbone.

-

★ Mechanism of ActionStrongly Hydrophobic & Fluid. The three unsaturated hydrocarbon chains confer a strongly hydrophobic nature and liquid consistency. This makes it insoluble in water but ensures excellent compatibility with edible oils.

Specifications:

Key features include:

- Yellow to amber oily liquid

- Odorless or with a faint characteristic odor

- Insoluble in water but dispersible in vegetable and mineral oils

- Excellent stability in typical storage conditions

- Especially effective in stabilizing W/O emulsions

| Test Item | Unit | Minimum Value | Maximum Value |

|---|---|---|---|

| HLB value | —— | 1.8 | |

| Saponification Value | mgKOH/g | 165 | 180 |

| Iodine Value | mgKOH/g | 60 | 80 |

| Acid Value | mgKOH/g | — | 15 |

| Moisture | % | — | 1.5 |

Applications:

- Oil & Gas (Drilling Fluids): Used in oil-based drilling muds to maintain emulsion stability and viscosity under high pressure and temperature.

- Industrial Explosives: The primary emulsifier for stabilizing the “oxidizer-in-fuel” matrix of emulsion explosives, ensuring safety and shelf life.

- Cosmetics & Personal Care: Acts as a dispersing agent for pigments in lipsticks and foundations, and as an emulsifier in cleansing oils.

- Textile & Leather Processing: Provides superior lubrication and softening properties to fibers and leather due to its high oil content

Ultra-Low HLB (1.8)

With one of the lowest HLB values available, Span 85 is the ultimate choice for systems that are predominantly oil. It stabilizes inverse emulsions that other surfactants cannot handle.

Superior Pigment Wetting

Its trioleate structure allows it to thoroughly coat solid particles (like pigments or minerals), preventing them from clumping and ensuring a smooth, uniform dispersion in oil bases.

High Lubricity

Featuring three oleic acid tails, it offers exceptional lubricity and friction reduction, making it valuable in metalworking fluids and textile spinning lubricants.

Inverse Emulsion Stability

Critical for the explosives industry, it creates a robust barrier around water droplets within an oil phase, preventing premature coalescence even during long storage.

storage & package

Storage:

Store in a cool, dry, and well-ventilated area, away from direct sunlight and sources of heat.

Avoid contact with harmful or incompatible substances. Handle with care during transportation to prevent leakage or contamination.

Transportation:

Transport as a general chemical product, following standard safety and handling procedures.

Package:

Sorbitan Trioleate is packed in high-quality PE drums with double-seal lids.

Standard packaging sizes include 25kg/drum, 200kg/drum, and 1000kg IBC tote to meet different usage needs.