In the global food industry, the INS 47x series—specifically Mono- and Diglycerides (INS 471), DATEM (INS 472e), and Polyglycerol Esters (INS 475)—are widely regarded as the “gold standard” for bakery and dairy products.

However, as food manufacturers expand into beverages, sauces, and functional liquids, many R&D teams hit a “performance wall.” They often find that their trusted INS 471 fails to keep a beverage clear or prevent a salad dressing from separating.

In this comprehensive guide, we will first dive deep into the chemistry of the INS 47x series, and then explore why adding Sorbitan Esters (Span) and Polysorbates (Tween) to your portfolio is the key to solving complex stability challenges.

Part 1: The Technical Deep Dive – Understanding the INS 47x Series

To understand why you might need other emulsifiers, you must first understand what INS 47x emulsifiers are and how they work.

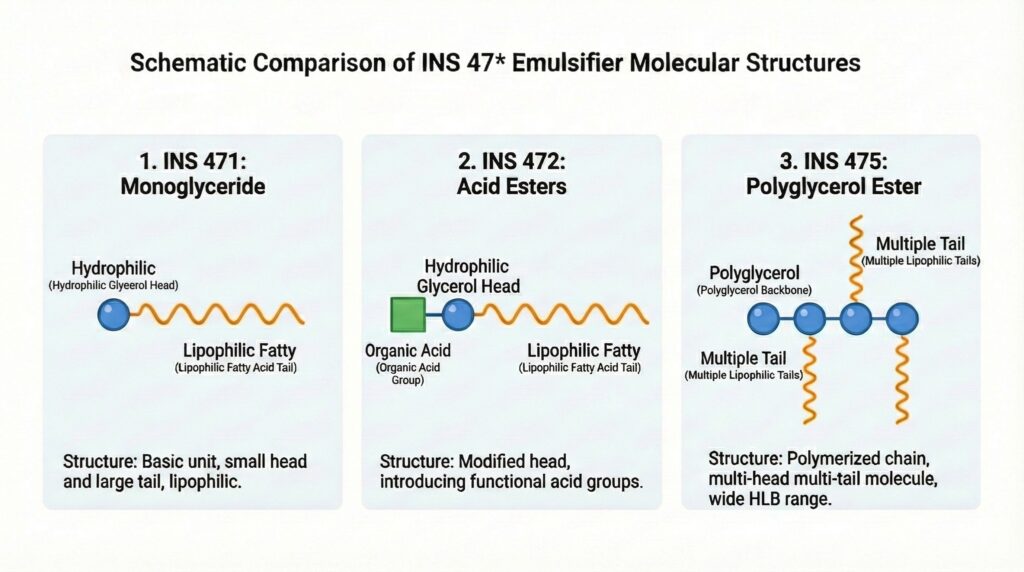

1. INS 471: Mono- and Diglycerides of Fatty Acids

- The “Base Unit”: This is the most fundamental food emulsifier.

- Source & Structure: Derived from glycerol and fatty acids (usually from palm oil or stearic acid). It consists of a hydrophilic glycerol head and a lipophilic fatty acid tail.

- Function: It is primarily a Texturizer. With a low HLB (3-4), it excels at interacting with starch to prevent bread staling (softening) and controlling fat crystallization in margarine.

- Physical Form: Typically solid beads or powder that require heating to melt (approx. 60°C+).

2. INS 472 Series: Acid Esters of Mono- and Diglycerides

- The “Modified Unit”: These are created by reacting INS 471 with organic acids to change their functionality.

- DATEM (INS 472e): Reacted with Diacetyl Tartaric Acid. It carries a charge that binds strongly to gluten proteins, making it the “King of Volume” in bread making.

- LACTEM (INS 472b): Reacted with Lactic Acid. It excels at stabilizing air bubbles, making it ideal for whipped toppings and mousses.

3. INS 475: Polyglycerol Esters of Fatty Acids (PGE)

- The “Polymer Chain”: Instead of a single glycerol, INS 475 uses a polymerized chain of glycerols.

- Function: This “multi-headed” structure allows it to form a thick, stable film around air bubbles. It is the core ingredient in Cake Gels, allowing sponges to rise high without collapsing.

Part 2: The Limitation – Why INS 47x Isn’t Enough

While INS 47x emulsifiers are powerful, they have limitations:

- Low HLB: Most are lipophilic (oil-loving). They struggle to stabilize Oil-in-Water (O/W) systems like beverages or milk tea.

- Solubility: They are often solids that do not dissolve easily in cold water.

- Clarity: They cannot solubilize essential oils into transparent liquids.

This is where the Span (INS 49x) and Tween (INS 43x) series become essential.

Part 3: The Comparison – Texturizers vs. Solubilizers

The table below highlights why Span and Tween are the perfect complement to your existing INS 47x usage.

| Feature | INS 47* (471/472/475) | Span (INS 49x) & Tween (INS 43x) |

|---|---|---|

| Primary Function | Texturizer (Softness, Crystal Control) | Solubilizer & Emulsifier (Stability, Clarity) |

| HLB Range | Low (3-10) | Wide Range (1.8 to 16.7) |

| Physical Form | Mostly Solid (Beads/Powder) | Mostly Liquid or Paste |

| Key Advantage | Interacts with Starch/Protein | Reduces Surface Tension Rapidly |

| Best Application | Bread, Cake, Margarine | Beverages, Sauces, Ice Cream |

The “Liquid Advantage”

Unlike INS 471, which must be melted, Polysorbates (Tweens) are liquids. This makes them incredibly easy to dose in automated beverage lines or cold-process sauce manufacturing, saving energy and processing time.

Part 4: Real-World Applications (Case Studies)

Here are three common scenarios where switching to or adding Span/Tween solves specific industrial pain points:

Scenario 1: The Beverage “Oil Ring”

- Challenge: A manufacturer found a ring of essential oil floating at the neck of their fruit drink bottles. INS 471 could not dissolve the oil.

- Solution: Polysorbate 80 (Tween 80 / INS 433).

- Why: With a high HLB of 15.0, Tween 80 acts as a solubilizer, breaking the oil down into micro-particles that remain invisible and suspended in water, ensuring a crystal-clear product.

Scenario 2: Separation in Sauces

- Challenge: A salad dressing formula was separating (oil floating on top) after two weeks.

- Solution: Polysorbate 60 (Tween 60 / INS 435) combined with Xanthan Gum.

- Why: Liquid sauces require a strong O/W emulsifier. Tween 60 creates a robust barrier around oil droplets, preventing them from merging.

Scenario 3: The Bakery Synergy

- Challenge: A bakery wanted to improve dough machining tolerance without increasing costs.

- Solution: Combining INS 471 with Sorbitan Monostearate (Span 60 / INS 491).

- Why: You don’t have to choose just one. Span 60 works synergistically with INS 471 to strengthen the gluten network while keeping the crumb soft.

Part 5: Quality Assurance & Supply

At FoodEmul, we understand that introducing a new additive requires trust in the supply chain.

- Production Power: Our manufacturing base boasts an annual capacity of 150,000 tons, ensuring stable supply even during market fluctuations.

- Certified Quality: We provide full ISO 22000, Kosher, and Halal certifications. Our products are fully compliant with Codex Alimentarius standards, making them ready for export to Vietnam, Southeast Asia, and global markets.

Conclusion: Complete Your Toolkit

If your portfolio relies solely on INS 471, 472, and 475, you are perfectly equipped for bakery and solid fats. However, to capture the growing market for beverages, liquid dairy, and sauces, the Span and Tween series are the missing pieces of your puzzle.

Ready to test the difference?

We offer FREE SAMPLES for your R&D trials. Whether you need the high-clarity solubilization of Tween 80 or the dough-strengthening power of Span 60, we are here to support your formulation.

Contact us today to request your sample kit:

- Email: Joe@foodemul.com

- WhatsApp: +86-13393315821

- Website: www.foodemul.com