Overview

-

Chemical NatureSpecialized non-ionic surfactant characterized by its Tristearate structure (three stearic acid chains).

-

Appearance & SpecsWaxy solid | HLB Value: 10.5

-

★ Primary Application (Frozen Desserts)Preventing Heat Shock. Offers superior fat-destabilization properties. The industry standard for maintaining texture in ice cream and preventing heat shock.

-

Industrial UseEffective at controlling foam in fermentation processes.

-

Key FunctionsFat Destabilizer & Foam Control Agent.

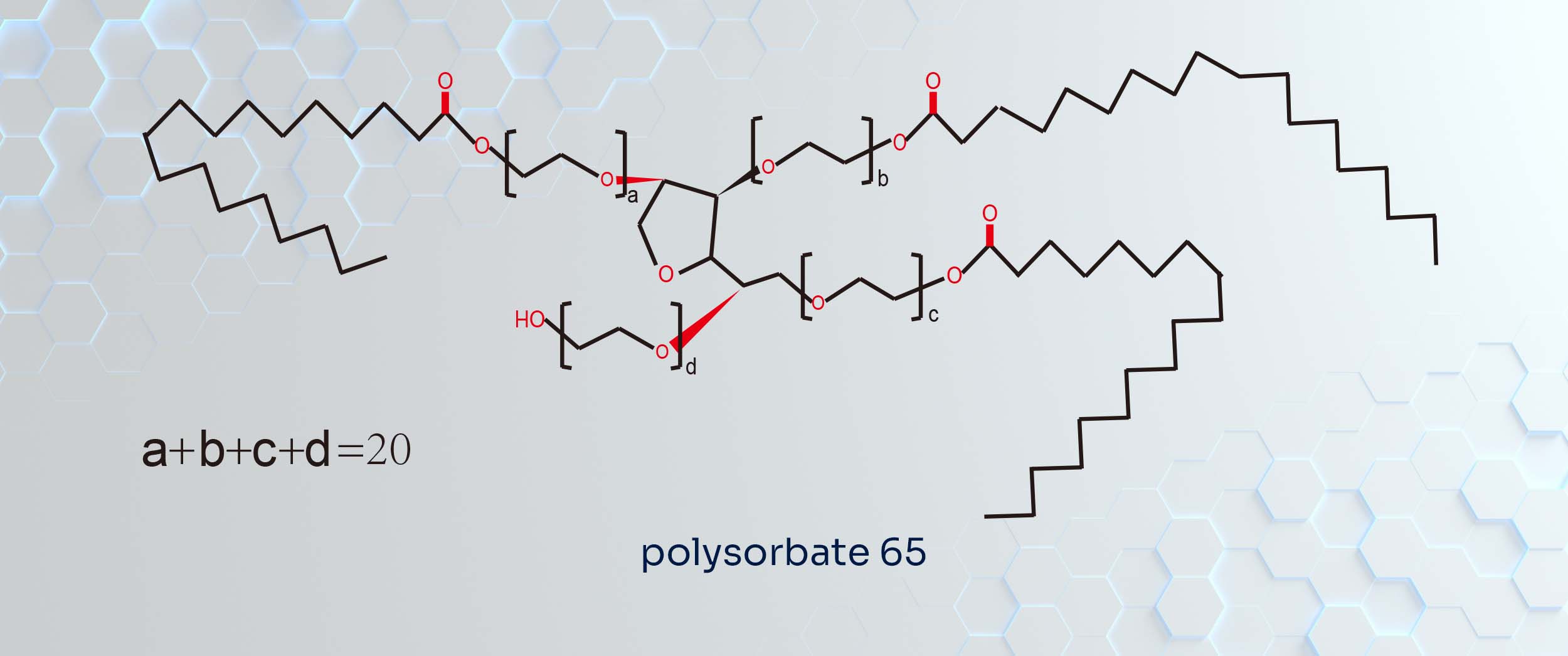

Molecular Structure

-

Structural ComponentsHydrophilic Segment: Polyoxyethylene chain introduced through ethylene oxide units (approx 20, enhancing water affinity).Hydrophobic Moiety: Formed by three stearic acid residues (Tristearate) esterified to the core, providing significant lipophilicity.Backbone: Sorbitan (sorbitol-derived dehydrated ring) linking the hydrophobic and hydrophilic segments.

-

★ Mechanism of ActionSurface Tension Reduction. This amphiphilic structure allows Polysorbate 65 to adsorb at the oil–water interface. Despite its high stearic acid content, the ethoxylation enables it to act as a reliable O/W emulsifier and stabilizer.

Specifications:

| Test Indicator | Unit | Min Value | Max Value |

|---|---|---|---|

| HLB Value | — | 10.5 | |

| Saponification Value | mgKOH/g | 88 | 98 |

| Hydroxyl Value | mgKOH/g | 44 | 60 |

| Acid Value | mgKOH/g | - | 2.0 |

| Moisture Content | % | - | 3 |

Applications:

- Frozen Desserts (Ice Cream): The primary application. It controls fat agglomeration and prevents “heat shock” (ice crystal growth) during storage and transport, ensuring a dry, creamy texture.

- Whipped Toppings & Aerated Fillings: Stabilizes the foam structure in non-dairy whipped creams, ensuring high overrun and stiffness.

- Bakeries (Cake Mixes): Used in cake mixes to improve batter aeration and volume.

- Processing Aid (Anti-Foaming): Acts as a defoamer during sugar processing and fermentation due to its tristearate structure.

Ultimate Heat Shock Resistance (Anti-Melting)

Polysorbate 65 is unrivaled in protecting ice cream texture against temperature fluctuations. It prevents the formation of coarse ice crystals, keeping the product smooth even after partial thawing and refreezing.

Dryness & Shape Retention

Promotes controlled fat destabilization, creating a ‘dry’ ice cream extrusion that holds its shape perfectly and resists melting, crucial for soft-serve and novelty bars.

High-Stability Foam Structure

In whipped toppings, the Tristearate structure creates a robust film around air bubbles, preventing collapse and weeping (syneresis) over time

Effective Defoaming Action

Uniquely functions as a processing aid to reduce unwanted foam during industrial mixing and fermentation, unlike the high-foaming Tween 20.

storage & package:

Storage:

Store in a cool, dry, and well-ventilated area, away from direct sunlight and sources of heat.

Avoid contact with harmful or incompatible substances. Handle with care during transportation to prevent leakage or contamination.

Transportation:

Transport as a general chemical product, following standard safety and handling procedures.

Package:

Polysorbate 65 is packed in high-quality PE drums with double-seal lids.

Standard packaging sizes include 25kg/drum, 200kg/drum, and 1000kg IBC tote to meet different usage needs.