Overview

-

Chemical NatureNon-ionic surfactant derived from sorbitan and lauric acid.

-

Appearance & SpecsViscous amber liquid | HLB Value: 8.6

-

★ Primary Application (Yeast)Industry-Standard Protectant. Preserves cell viability for Instant Dry Yeast during drying and acts as a rehydration aid.

-

Cosmetics UseFunctions as a light, non-greasy emollient.

-

Key FunctionsWetting agent & Rehydration aid.

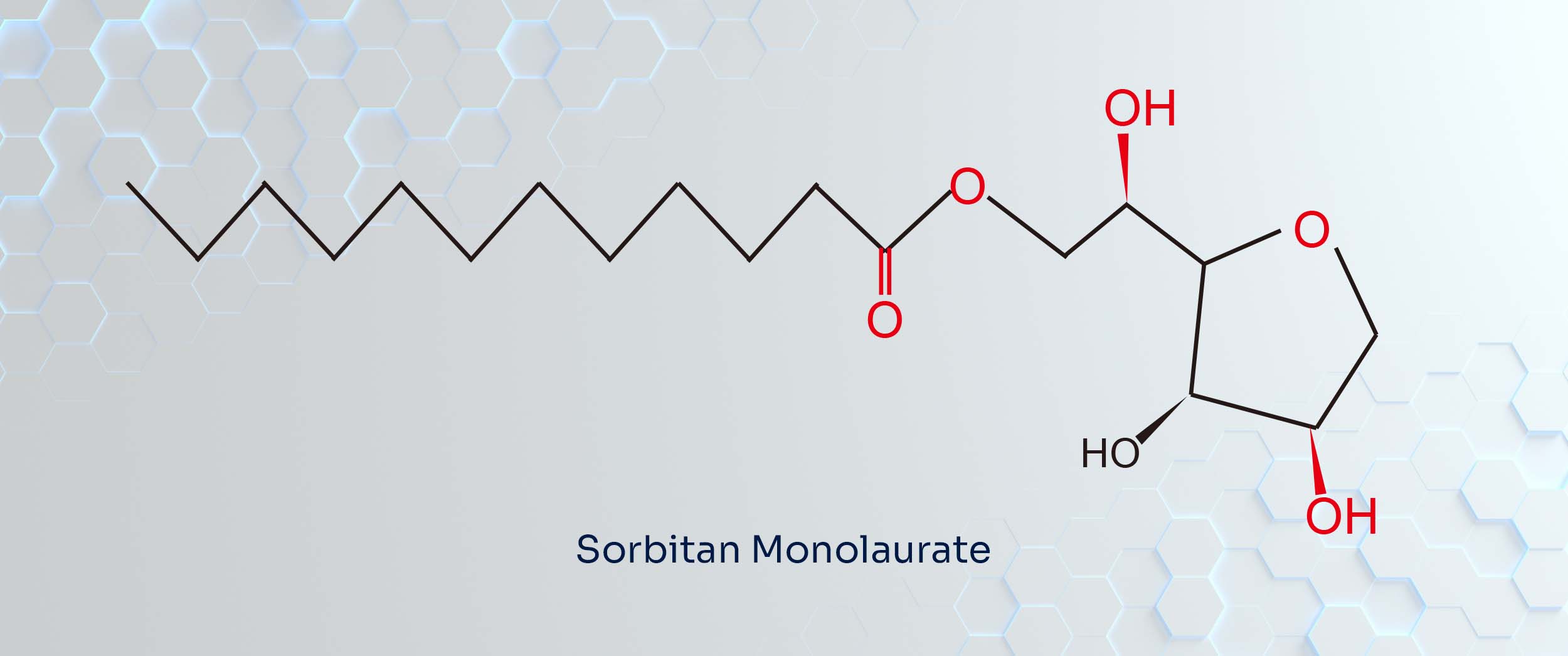

Molecular Structure

-

Structural ComponentsHydrophilic Backbone: Sorbitan (derived from sorbitol dehydration).Hydrophobic Moiety: Lauric acid (C12 fatty acid) esterified to sorbitan.

-

★ Mechanism of ActionAmphiphilic Nature. The structure allows the compound to align perfectly at oil-water interfaces. This effectively reduces surface tension and stabilizes emulsions.

Specifications:

| Test Item | Unit | Minimum Value | Maximum Value |

|---|---|---|---|

| HLB value | —— | 8.6 | |

| Saponification value | mg KOH/g | 155 | 170 |

| Hydroxyl value | mg KOH/g | 330 | 360 |

| Acid value | mg KOH/g | — | 7 |

| Moisture | % | — | 1.5 |

| Fatty acid content | w% | 56 | 68 |

| Polyol content | w% | 36 | 49 |

| Ash residue (on ignition) | w% | — | 0.5 |

| Sulfur (S) | mg/kg | — | 3 |

| Lead (Pb) | mg/kg | — | 2 |

Applications:

- Dry Yeast Manufacturing: Added to yeast prior to drying to protect cell membranes and facilitate rapid rehydration when used by bakers.

- Cosmetics & Skincare: A low-HLB co-emulsifier used in lightweight lotions and creams to improve spreadability without a greasy feel.

- Food Antifoaming: Acts as an antifoaming agent in sugar processing and milk production.

- Industrial Lubricants: Used as a rust inhibitor and lubricant additive in metalworking fluids due to its surface-active lauric chain.

Yeast Cell Protection

Span 20 forms a protective film around yeast cells, significantly improving their survival rate during the drying process and restoring activity quickly upon rehydration.

Superior Wetting Agent

With its lauric acid backbone, it offers excellent wetting properties, helping powders (like milk powder or cocoa) disperse instantly into water without clumping.

Light Texture (Cosmetics)

Unlike heavier stearate emulsifiers, Monolaurate provides a ‘light’ and dry skin feel, making it ideal for formulating non-greasy lotions and sunscreens.

HLB 8.6 Co-Emulsifier

Functions as a perfect bridge between oil and water phases. When paired with Polysorbate 20 (Tween 20), it creates highly stable, fine-textured emulsions.

storage & package:

Storage:

Store in a cool, dry, and well-ventilated area, away from direct sunlight and sources of heat.

Avoid contact with harmful or incompatible substances. Handle with care during transportation to prevent leakage or contamination.

Transportation:

Transport as a general chemical product, following standard safety and handling procedures.

Package:

Sorbitan Monolaurate is packed in high-quality PE drums with double-seal lids.

Standard packaging sizes include 25kg/drum, 200kg/drum, and 1000kg IBC tote to meet different usage needs.