Overview

-

Chemical NatureNon-ionic surfactant derived from the esterification of sorbitol with oleic acid.

-

Appearance & SpecsPale yellow to amber oily liquid | HLB Value: ~4.3

-

★ Primary Application (Emulsification)W/O Emulsion Specialist. Especially effective at stabilizing water-in-oil emulsions. Provides texture control and stability in fat-rich formulations.

-

Additional RolesFunctions as a dispersant and lubricant in various industrial applications.

-

Key FunctionsW/O Emulsifier & Lubricant.

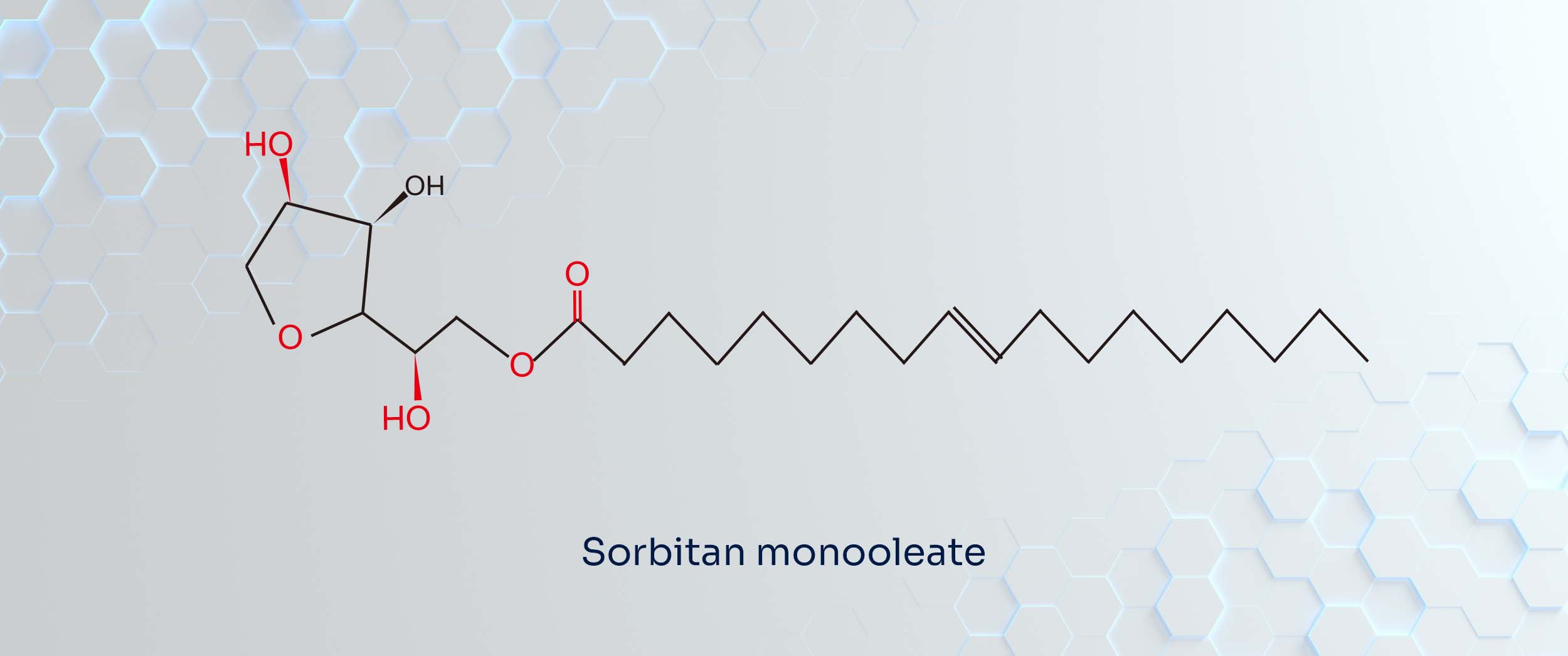

Molecular Structure

-

Structural ComponentsHydrophilic Core: Sorbitan (anhydrosorbitol) ring structure.Hydrophobic Moiety: Single oleic acid molecule esterified to the core.

-

★ Mechanism of ActionFluidity & Lipophilicity. The long oleic acid chain imparts fluidity and strong compatibility with lipid phases. While it has some hydrophilic balance, it is predominantly lipophilic, making it insoluble in water but ideal for dispersing in oils and stabilizing W/O emulsions.

Specifications:

Key qualitative attributes include:

- Amber to pale yellow oily liquid form

- Minimal characteristic odor

- Insoluble in water; dispersible and compatible with lipid systems

- Stable under normal processing and storage conditions

- Works synergistically with stronger hydrophilic surfactants (e.g., polysorbates) to tailor custom HLB systems

| Test Item | Unit | Minimum Value | Maximum Value |

|---|---|---|---|

| HLB value | —— | 4.3 | |

| Saponification Value | mgKOH/g | 145 | 160 |

| Iodine Value | mgKOH/g | 193 | 210 |

| Acid Value | mgKOH/g | — | 8 |

| Moisture | % | — | 2 |

| Fatty Acids | w% | 73 | 77 |

| Polyol | w% | 28 | 32 |

| Phosphorus | mg/kg | — | 3 |

| Lead | mg/kg | — | 2 |

Applications:

- Textile & Fiber: Acts as a smoothing lubricant and antistatic agent for synthetic fibers, preventing breakage during high-speed spinning.

- Industrial Explosives: The primary emulsifier used to stabilize emulsion explosives (matrix), allowing for safe storage and transport.

- Cosmetics: Used in “rich” night creams and ointments to create Water-in-Oil emulsions that provide a protective barrier on the skin.

- Food Processing: Functions as a defoamer in yeast production and sugar refining, and as a dispersant for oil-soluble colors.

Superior W/O Emulsification

With a low HLB of 4.3, Span 80 is the ideal choice for creating stable Water-in-Oil emulsions, where water droplets are suspended within a continuous oil phase.

High Lubricity (Oleic Source)

Derived from unsaturated Oleic Acid, it offers excellent surface lubrication properties, making it essential for reducing friction in textile manufacturing and metalworking.

The Perfect Tween 80 Partner

Span 80 and Tween 80 are the industry’s most common ‘power couple.’ Mixing them allows formulators to hit any specific HLB target between 4.3 and 15.0 for customized stability.

Liquid Handling

Unlike Span 40 or 60 (which are solids), Span 80 is a liquid at room temperature, making it easy to pump, pour, and mix into cold-process formulations without heating.

storage & package:

Storage:

Store in a cool, dry, and well-ventilated area, away from direct sunlight and sources of heat.

Avoid contact with harmful or incompatible substances. Handle with care during transportation to prevent leakage or contamination.

Transportation:

Transport as a general chemical product, following standard safety and handling procedures.

Package:

Sorbitan Monooleate is packed in high-quality PE drums with double-seal lids.

Standard packaging sizes include 25kg/drum, 200kg/drum, and 1000kg IBC tote to meet different usage needs.